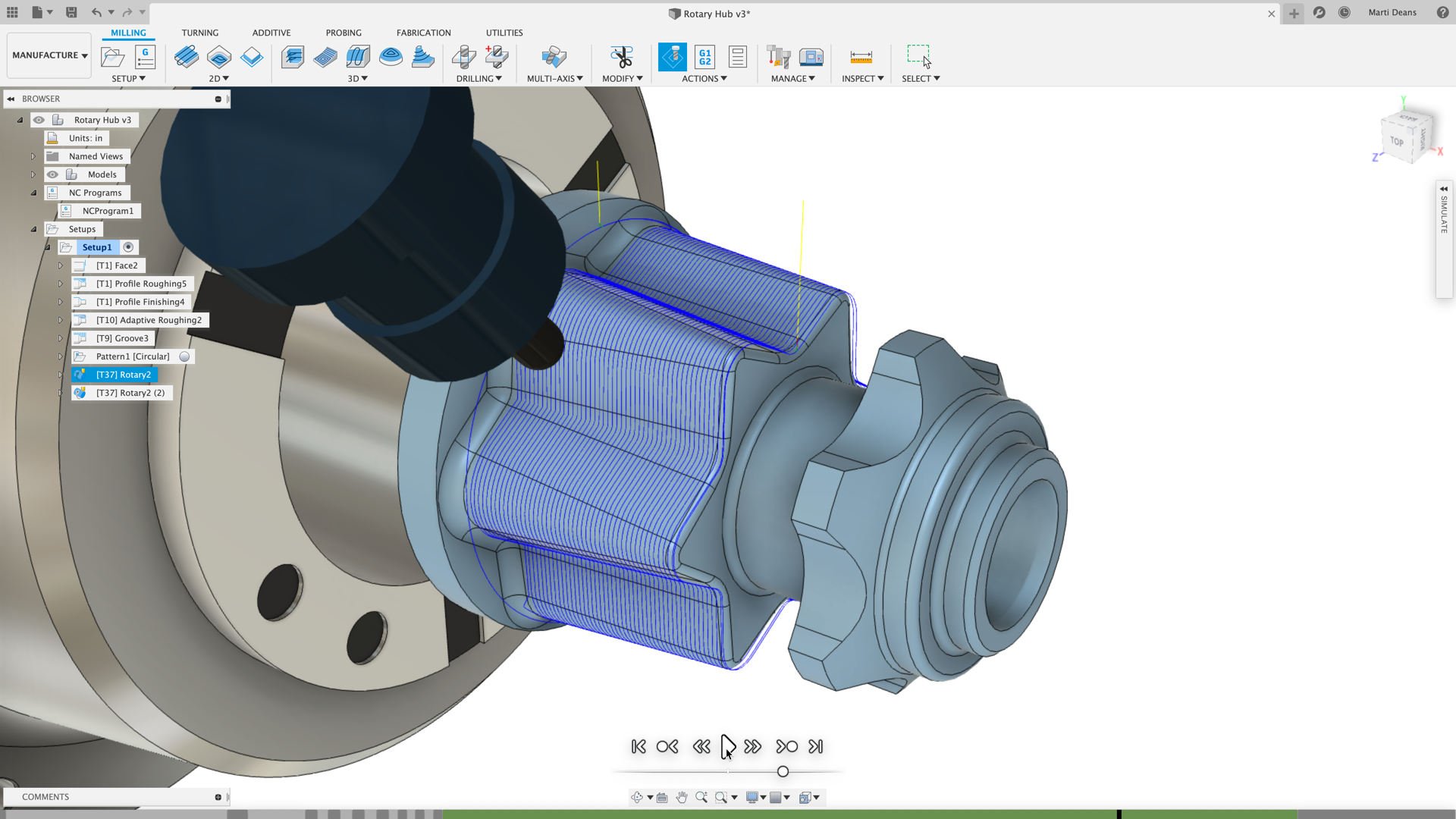

Software: Prusaslicer 2.4.0 (for optional STL modification) & Autodesk Fusion 360 Model to be machined: Owl CNC High Detail by billywoodworks found here: Owl CNC High Detail by billywoodworks - Thingiverse Tools: 3.175mm (1/8") 2-flute up-spiral flat end mill for roughing 20 Degree Engraving bit for finishing. Materials and Machinery in this tutorial:

Please read the entire guide before attempting.

There will also be some optional G-code changes and sizing done in other programs to achieve a better result.ĭisclaimer: I am in no way responsible for any possible damage to your machine or materials, although risk is very minimal if you follow along exactly as I am going to include images of my settings, setup, and results as I’ll be carving this. This guide assumes you know some basics of running the CNC, such as being able to jog the machine with the control app, set work origin, and set origins for the axes independently. In a bit of a follow up to my Laser Guide and Rotary CNC Guide, I’ve decided to do a quick 3d relief guide for the snapmaker using Fusion 360.

0 kommentar(er)

0 kommentar(er)